Beltwagon (Mobile Transfer Conveyor)

.jpg)

Beltwagons, or mobile transfer conveyors (MTCs), designed as an intermediate link between the crushing station or excavator and the downstream equipment in bulk material transport applications, are widely used for the mining process of various large-scale mines (coal mine, non-coal mine) and the excavation projects of large-scale earthworks, gravels and rocks. ?? The design can be distinguished in fully-mobile MTCs (A type MTCs) and semi-mobile MTCs (B type MTCs).?? NHI MTCs are dedicatedly engineered to suit the requirement of medium to large mines. A modular system enables the delivery of equipment of high efficiency and capacity at low costs. Compact construction, light weight, energy conservation, better environment performance, safety, stability and reliability are key quality of our product. They have a wide range of models and sizes in capacities ranging from 1500t/h to 10000t/h. The spreaders of specific models and sizes can also be tailor-engineered for the application and built to order to meet the requirement of the client and the site conditions.?? The main customers of this product include China coal Pingshuo Group Co. Ltd.

Northen Heavy Industries Group(NHI)

Bucket Wheel Excavator

Bucket wheel excavator is a key machine to complete mining and excavation application in the continuous mining, transportation and discharge process. It is applied to the large-scale project with great amount of exploitation and long length of service, in particular, to applications in open-pit mines and large-scale earthworks. Bucket wheel excavator can operate continuously with high efficiency and low consumption. The bucket wheel excavator can be used for rock stripping operations as an alternative solution for drilling and blasting process. The machine can effectively reduce harmful emissions in aspect of environmental protection. Besides, bucket wheel excavator is applicable for the exploitation of soft mines in good occurrence conditions.?? Depending on the equipment structure and rated production rate, the bucket wheel excavator can be categorized as discharge connecting bridge type for large-scale mining application, discharge boom type for compact type mining application and discharge connecting bridge type for giant mining application.?? The bucket wheel excavator is a kind of mining machine which can work continuously. And it presents the features of small linear size, light weight, large excavation capacity, high production rate, excellent adaptability and outstanding energy conservation and environmental protection performance. The machine is of widespread applications in not only the overburden stripping and mining operations, but also the works for roads, dams, canals, artificial lakes, foundation construction of large projects, reclaiming farmland from waters and large open-pit stockyards. Our company can provide various standard type- and extended-length type bucket wheel excavators driven either by diesel engines or electric drives. The machines can also be tailor-engineered to suit the client’s the requirements.

Northen Heavy Industries Group(NHI)

Fully-mobile crushing station

Fully-mobile crushing station is a common crushing system offering solutions for crushing various ores and lump-sized materials for mine smelting industry, building material industry, roads, railways, water conservancy and chemical industries. Depending on the different crushing equipment applied, this crushing systems comes in several types like crushing station with toothed roll crusher, crushing station with toothed roll crusher and screening facilities, and crushing station with jaw crusher. Our fully-mobile crushing stations are designed and supplied incorporating new patent technology for workface mining applications. Low cost and compact type engineering solutions have been applied for this product and particular emphasis has been given to the flexibility of the equipment and its related systems. The system has the capacity ranging from 500 to 5000 tons per hour. It can be custom engineered and made to order to suit the client’s needs and actual operation conditions. The main customers of this product include China coal Pingshuo Group co. Ltd.

Northen Heavy Industries Group(NHI)

Semi-Mobile Crushing Station

Semi-mobile crushing station is a common crushing system offering solutions for crushing the lump-sized materials like coals, ores and rocks covering such fields as mine (coal mine and non-coal mine), metallurgy industry, road, and chemical industry. Following the shifting and relocating modes, skid-mounted semi-crushing station and semi-stationary crushing station can be included; following the crushing modes, the semi-mobile stations respectively equipped with hydraulic gyratory crusher, toothed roll crusher and jaw crusher are included. With many years of experience in designing, manufacturing and modifying semi-mobile crushing stations, NHI can offer a wide range of semi-mobile crushing stations with crushing capacities ranging from 500t/h to 10000t/h. We have provided customized crushing system for many weld-known companies in mine, chemical and iron & steel industries. With years of persistent efforts in upgrading and optimizing the structures of the semi-mobile crushing station, we have got comparatively mature engineering capability in structural modular design of the primary section of semi-mobile crushing station. We can design and manufacture the crushing system featuring simple structure, stable operation, reliable performance, and easy installation, operation and maintenance. The semi-mobile crushing station with capacity above 6000t/h has become one of the star products in our company.

Northen Heavy Industries Group(NHI)

Spreader

Spreaders are the machine offering stacking and discharging solutions for bulk materials at the dump sites or end of the lines of other bulk material conveying and discharging applications, widely used for the mining process of various large-scale mines (coal mine, non-coal mine) and the excavation projects of large-scale earthworks, gravels and rocks. ?? The spreader shall be sorted by its structure into boom type, single support type, single C frame type, double C frame type, double support type and extension type. It can also be sorted by its type of traveling unit into crawler type, walking type, track type and walking track type spreaders.?? NHI spreader has advantages of simple structure, good movability, easy installation, operation and maintenance and stable and reliable service. The machine has a wind range of models with capacities ranging from 1500t/h to 10000t/h, length ranging from 30m to 300m and equipment working weight varying from 50 tons to 4000 tons. To suit the applications in special conditions, a mobile cross-pit spreader system is developed with discharging boom length as 200 meters. The spreaders of specific models and sizes can also be tailor-engineered for the application and built to order to meet the requirement of the client and the site conditions. ? Our spreaders has been mainly applied in Kazakhstan.

Northen Heavy Industries Group(NHI)

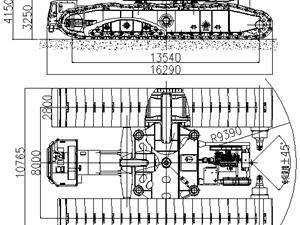

Transport Crawler

Transport crawlers are commonly used as heavy-duty, crawler-based and special mining vehicles. It is extensively applied for the relocation of medium-to-large equipment (e.g. semi-mobile crushing station, belt conveyor drive station) used in large-scale semi-continuous, continuous and discontinuous open-pit mining process. Depending on its rated working capacity (playload), the transport crawlers can be categorized as light-duty transport crawler and heavy-duty transport crawler. Our transport crawlers are equipped with sophisticated automatic control system to continuously keep the load level even and ensure optimal motor control on rough terrain in different conditions. The features and benefits of our transport crawlers include compact structure, light weight, low cost and high efficiency. Based on years of research and development, engineering and production practices, NHI’s series of transport crawlers includes in playload 250t, 320 t, 1200t and other tonnages. We can design and produce the exact product specially tailored to the client’s requirement. Our main customers for this kind of machine include China Coal Pingshuo Group Co., Ltd.

Northen Heavy Industries Group(NHI)