Magnesium Alloy Cold Mill

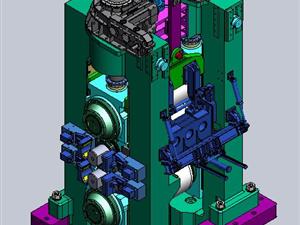

1.Scope of Application Magnesium alloy plate cold rolling mill refers to the strip rolled and trimmed at medium temperature and normal temperature. According to rolling process requirements of plate and strip materials, the strip is finally rolled into a strip with ideal thickness after a certain pass of rolling. According to the needs of different processes, it can be rolled into plates or coils. 2.Specification Name: 1650mm Magnesium Plate Cold Rolling Mill Rolling force (kN): 22000 3.Product Introduction Cold rolling mills can be classified into four high cold rolling mills and six high cold rolling mills according to the number of rolls, and it also can be classified into small rolling mills, medium rolling mills and large rolling mills according to the specifications. Most of the magnesium alloy cold rolling mills put into operation in the early stage are four high rolling mills, while the international mainstream products have been upgraded to six high cold rolling mills. Our company is an enterprise that designed and produced metallurgical rolling mills earlier in China. Over the years, we have provided many sets of cold rolling mills for major metallurgical manufacturers at home and abroad. Now NHI can produce large and medium-sized magnesium alloy cold rolling mills of various specifications. In 2013, our company successfully developed the first complete set of wide width high-performance magnesium alloy plate rolling equipment, namely 1650mm six high cold rolling mill, and obtained relevant patents. This unit has changed the history that there has been only sheet but no strip in the field of magnesium alloy cold rolling at home and abroad. NHI is a domestic magnesium alloy cold rolling mill manufacturer that can integrate R&D, design, production, commissioning and fully master all technologies. Its technical level plays an important role in the field of domestic magnesium alloy production equipment research and development. 4.Main Experiences in Recent Years Yingkou 1650mm aluminum magnesium six high cold rolling mill project

Northen Heavy Industries Group(NHI)

Magnesium Alloy Hot Mill

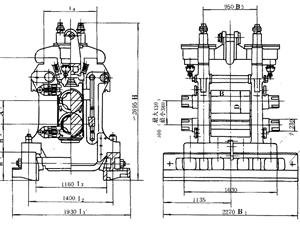

1.Scope of Application The magnesium hot rolling mill is mainly used to roll the hot rolled bloom of magnesium alloy ingots and the finished medium and heavy plates according to the needs of production process to produce qualified intermediate slabs and finished plates. The mechanical properties, dimensional tolerance and surface quality of magnesium plate products are directly determined by the installation level of hot rolling mill, such as process design concept, unit component configuration, control accuracy, etc. 2.Specification Name: 1725mm Magnesium Plate Hot Rolling Mill Rolling force (t): 3000t 3.Product Introduction Hot rolling mill is an important equipment in the metallurgical industry, in which the magnesium alloy plate hot rolling mill is used to roll the magnesium alloy slab with the maximum thickness of 300 mm in the hot state to the ideal thickness after multiple passes of horizontal and vertical rolling. The rolled plate and strip can be directly processed as finished products after finishing process, and can also be used as rolling raw materials for subsequent cold rolling equipment. Hot rolling mills for magnesium alloy plates are classified in many ways, including 2 high hot rolling mills and 4 high hot rolling mills according to the number of rolls, small rolling mills, medium rolling mills and large rolling mills according to the specifications, and horizontal rolling mills and vertical rolling mills according to the structure. Our company is an enterprise that designed and produced metallurgical rolling mills earlier in China. Over the years, we have provided dozens of hot rolling mills for major metallurgical manufacturers at home and abroad. Now NHI can produce large and medium-sized magnesium alloy hot rolling mills of various specifications. In 2013, NHI successfully developed a 1725mm four roll hot rolling unit for high-performance magnesium alloy plate rolling, of which the key equipment is a high stiffness and high load magnesium plate four roll hot rolling mill, which won the national invention patent. At present, NHI is a domestic magnesium alloy hot rolling mill manufacturer that can research, develop, design, produce, commission and fully master all technologies. Its technical level plays an important role in the field of domestic magnesium alloy production equipment research and development. 4.Main Experiences in Recent Years Yingkou 1725mm aluminum magnesium four high hot rolling mill project

Northen Heavy Industries Group(NHI)

Profile Rolling

1.Scope of Application Profile rolling mill is a kind of rolling equipment for ferrous metal profiles and non-ferrous metal profiles. According to different product uses and specifications, roll passes of different specifications are opened on the roll of profile rolling mill. According to the rolling process requirements, the incoming steel billets will be rolled into different specifications and types of products such as angle steel, I-beam steel, channel steel, etc. through several rolling mills or several passes. 2.Specification ? 300, ? 400, ? 500, ? 550 and ? 650 3.Product Introduction There are many classification methods for profile rolling mills, among which the nominal diameter of the roll is usually used for definition and classification, which can be divided into large rolling mills, medium rolling mills, and small rolling mills, such as those produced by our company ? 350/450 profile rolling mill; It can also be divided into single stand mill, horizontal mill, in-line mill, checkerboard mill, etc. according to different layout forms; It can also be divided into rail beam rolling mill, H-beam rolling mill, ball flat rolling mill, etc. according to different rolled steel varieties. Our company has been engaged in the design and manufacturing of section mill for more than 50 years, and the specifications are ? 300? ? 400? ? 500? ? 550? ? 650 and other section steel mills. In 2012, our company was a ball and flat steel mill produced by Angang Steel Large Plant, mainly producing military products with high efficiency and stable quality. The profile rolling mills of various specifications produced by our company are all of cast steel structure, open frame and AC/DC motor drive. Our company is an early manufacturer of the design and production of the domestic section steel mill. Whether it is a complete set of section steel mills or a single unit of equipment, it has the characteristics of reasonable structure, convenient maintenance, and reliable use, and has been praised by users. At present, NHI can design and produce a variety of profile rolling mills according to user requirements. 4.Main Experiences in Recent Years Tangshan Iron and Steel Co., Ltd., Baotou Iron and Steel Co., Ltd., Wuhan Iron and Steel Co., Ltd., etc

Northen Heavy Industries Group(NHI)

Steckel Mill

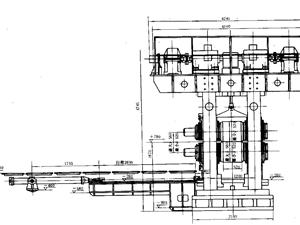

1.Scope of Application Steckel mill is a steel plate mill. In the 1930s, 1830mm steckel mill was first used in the United States. It was originally designed to produce thin coils. In recent years, due to development of automatic control technology of rolling mill, the design idea of new Steckel Mill is to simultaneously produce medium and heavy plates and hot rolled coils, as well as stainless steel and stainless steel clad plates. 2.Specification Roll length 1725mm 3.Product Introduction Steckel mill is generally divided into small mill, medium mill and large mill according to the product specification, that is, defined by the working length of the work roll body of the mill. The steckel mill developed by NHI is used to center the slab through the entrance centering device, and then after passing through the reversible mill several times, the slab can reach the coiling thickness of 10mm~25mm. As Steckel mill can realize multi pass rolling in one rolling mill production line and online heating, it reflects the advantages of Steckel mill as "compact, continuous and economical", which is very suitable for the development needs of small and medium-sized metallurgical enterprises. NHI is an early domestic manufacturer to develop steckel mill. It has cooperated with relevant international manufacturers for many times, and has fully mastered the complete set of steckel mill technology through transformation and absorption. In 2001, the complete set of steckel mill produced by our company was exported to Middle East countries, reflecting the technical strength of NHI in the field of steckel mill. At present, NHI can produce various specifications of steckel mills and related supporting equipment according to user requirements, and strive for perfection to serve users wholeheartedly. 4.Main Experiences in Recent Years 1725mm Steckel Mill Project

Northen Heavy Industries Group(NHI)

Strip Steel Mill

1.Scope of Application The strip mill is a production equipment for rolling ingots or billets into steel strips. The production of strip steel by rolling method has the advantages of high productivity, multiple varieties, strong production continuity, easy to realize mechanical automation, etc. The strip mill has wide application scope, high control accuracy and complex equipment, which can be used in both cold rolling workshop and hot rolling workshop. 2.Specification Product specification: maximum coil weight: 10t Maximum rolling force: ? 7000kN 3.Product Introduction There are two high strip mills and four high strip mills, both of which are horizontal roll mills. The 800mm four high single stand reversing cold rolling mill is a high-strength reversing cold rolling mill. The unit consists of a coil car, a decoiler, a process platform device in front of the machine, an 800mm four high cold rolling mill working train, a process platform device behind the machine, a coiler, a coil unloading car, and a roll change system. 4.Main Experiences in Recent Years Shenyang Dongbao, Shandong Laiwu, etc

Northen Heavy Industries Group(NHI)

Wheel Hub Rolling Mill

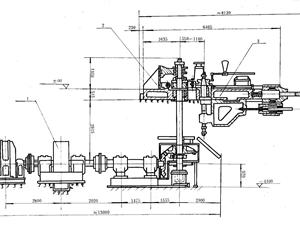

Hub rough mill is installed at the rear part of hub hydraulic press, for rolling wheel hub and other ring shape component, it is capable of making ring shape half product which is after hole drilling and pressing, and then transfer to finish rolling machining. Finish hub rolling machining is installed after rough rolling mill, for finish rolling machining ring shape component. While wheel rolling machine is used for rolling wheel spoke , which makes the diameter of part reach hot forging component standard, and shape rim, flat surface and flange. Slab type rolling mill can be categorized into two kinds as per its function; one is TCL-U1900 hub roughing mill, the other is TCL-J2500 hub rolling mill. Wheel rolling mill can be categorized into 7 roller horizontal wheel rolling mill and vertical DRAW wheel rolling mill. NHI started self-design and fabrication of hub rolling mill from 1960s, which is the first set of big equipment successfully installed and commissioned in China, which is rewarded by national tech conference medal on hub rolling mill in 1978. In November of 1977, rewarded by Key science and technology, for hub rolling mill, we already supplied 2 sets, one is for MAANSHAN steel company, which is mature technology, reliable quality, already used for many years. The other one was exported to north Korean in 1996. Now, NHI has mature technology in hub rolling mill and the supplier who is independent in technology developing and fabrication of hub rolling mill.

Northen Heavy Industries Group(NHI)